Tel/Whatsapp:+86 15649675999

Email:sale@kowloonmachine.com

Tel/Whatsapp:+86 15649675999

Email:sale@kowloonmachine.com

Article published:2023-09-27

Application and challenges of Double Shaft Shredder in processing solid film

The twin-shaft shredder is a key piece of equipment widely used in the waste treatment and recycling industry. Its powerful shredding capabilities and high efficiency make it ideal for processing a variety of materials. However, when it comes to rigid plastic materials like solid film, twin-shaft shredders can face some challenges. This article will discuss the applicability of a dual-shaft shredder when processing solid film, as well as the professional issues that may be involved.

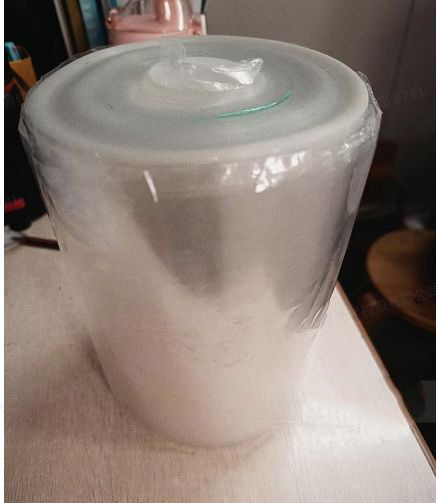

Characteristics of solid film

First, we need to understand the characteristics of solid adhesive film in order to better evaluate the suitability of a dual-shaft shredder for processing this material. Solid film is usually made of rigid plastic and has high hardness and rigidity. They are often used in packaging and manufacturing a variety of products such as plastic containers, bottles, toys, etc. Unlike soft plastic films, solid films are more difficult to handle because they cannot be easily torn or crushed.

solid film

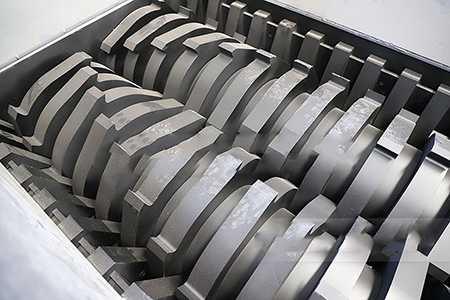

Working principle of double shaft shredder

Understanding how a twin-shaft shredder works is critical to evaluating its suitability for processing solid adhesive films. Double-shaft shredders usually consist of two rotating shafts with blades or hammers mounted on them. These blades or hammers cut, break and pulverize the material as they rotate. The dual-shaft design provides a smooth shredding process, but may also face some challenges when handling hard materials.

Challenges and responses

When processing solid film, a dual-shaft shredder may encounter the following challenges:

Rigidity and hardness: The hardness and rigidity of solid film make it less likely to be cut and torn. This may require a more powerful shredder with stronger blades or hammer heads to ensure effective shredding.

Size Matters: Solid adhesive films typically have larger dimensions, which may require a larger shredder to accommodate and process these materials. In addition, a proper material feeding system is required to ensure that the solid film can enter the shredder evenly.

Safety issues: The crushing of solid film may produce sharp fragments, and appropriate safety measures need to be taken to prevent operator injury and ensure safe handling of fragments.

To address these challenges, consider the following measures:

Choose a suitable twin-shaft shredder: Choose a shredder with sufficient power and strong blades based on actual needs to ensure effective shredding.

Material pretreatment: Before feeding the solid film into the shredder, you can consider preliminary processing of the material, such as cutting it into smaller pieces, to reduce the workload of the shredder.

Safety Measures: Operators should wear appropriate protective equipment such as gloves and goggles to ensure safety.

In general, the dual-shaft shredder may have certain applicability when processing solid film, but it is necessary to select the appropriate equipment and take appropriate pre-treatment and safety measures according to the actual situation. The rigidity and hardness of solid film make it relatively complex, but under the right conditions, a twin-shaft shredder can effectively process this material, providing important support for waste recycling and reuse. Ultimate success depends on the correct selection of equipment, the development of operating procedures, and an emphasis on safety and efficiency.