Tel/Whatsapp:+86 15649675999

Email:sale@kowloonmachine.com

Tel/Whatsapp:+86 15649675999

Email:sale@kowloonmachine.com

Application Materials:

All kinds of waste paper, waste cartons, cardboard, newspapers, paper factory waste, paper factory edge foot material, and all kinds of paper factory waste, paper waste, paper waste, etc..

Power:15kw-160kw

Working Capacity :5-60t/h

Waste paper recycling is a process of repeated papermaking, mainly recycling paper fibers in waste paper, which can greatly save resources and reduce pollutant emissions. In foreign countries, waste paper has the reputation of urban forest resources. Whether it is waste newspapers, book paper, office paper, or kraft paper, cardboard boxes, corrugated paper, etc., they are all valuable fiber raw materials used in papermaking. Using waste paper to make paper has the advantages of low energy consumption, low processing cost, low unit raw material cost, and reduced environmental pollution. Therefore, paper and cardboard produced from recycled fibers are called green products. The waste paper shredder is a special equipment for waste paper and waste board. The unique design idea and processing technology of the waste paper shredder can make any shape of waste corrugated paper, cardboard, newspapers, waste books, cartons, paper tubes, paper tubes, cardboards. Wait for the material to be quickly processed into small pieces and collected to ensure that there is no dust.

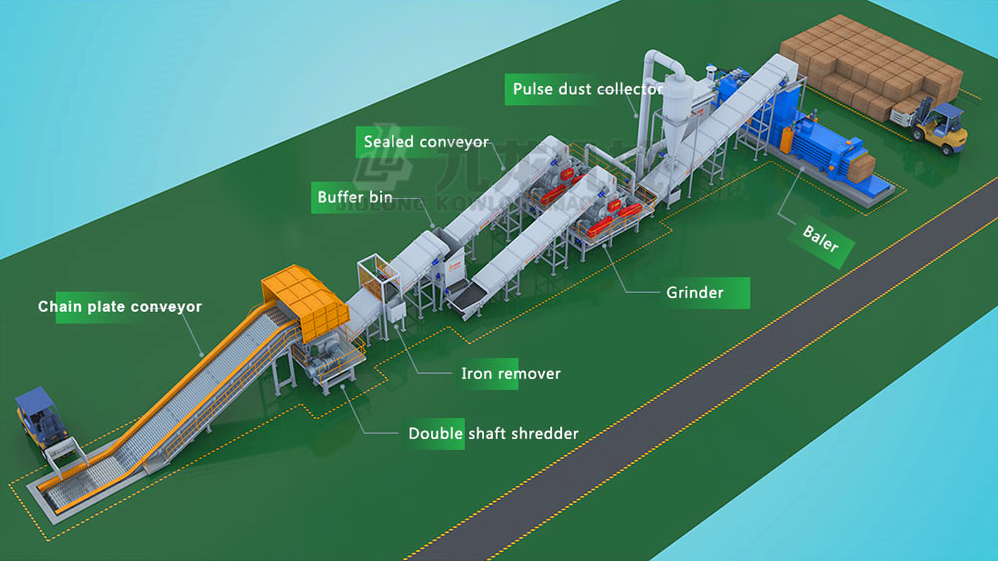

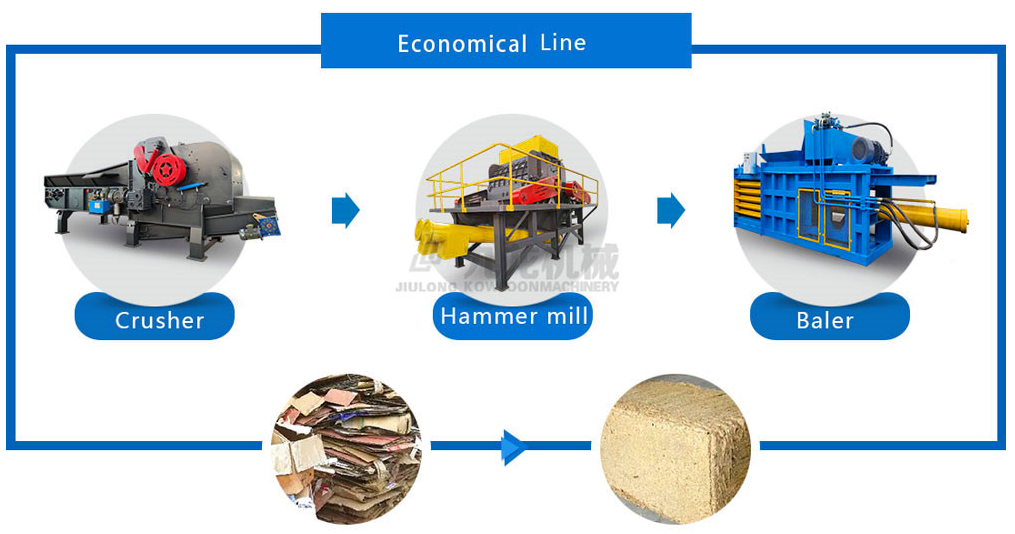

Crushing Section

Waste paper is sent to the chain conveyor by a mechanical grab, and enters the shredder's crushing chamber, then the shredder shreds it through blades’ cutting and tearing. The shredded scrap paper is sent to the buffer bin through belt conveyor. In the middle of the belt conveyor, there is a powerful electromagnetic self-unloading iron remover, which is used to absorb iron impurities such as nails in waste paper materials. The clean waste paper will enter the buffer bin.

Pulping Section

The crushed iron-removed scrap paper is sent from buffer distribution bin to two variable frequency feeding conveyors respectively, then is uniformly fed into the intelligent composite waste paper pulping machine through one distributing device. After being crushed by the high-speed multi-hammers rotor, the waste scrap paper is made into fibrous form at one time through a special screen. After being pre-compressed by the lower double screw conveyors, fibrous products are twisted to the feeding conveyor of baler. Then through the feeding conveyor, they are fed into the baler for the baling process.

In view of the fire risk of dust-free dry pulping, this pulping system is specially equipped with a water-blocking water mist spray device, to prevent open flames from entering the pulse dust collector and causing major safety accidents.

Features

1. Thick and heavy moving knives have high crushing efficiency. The knives are all cast with alloy steel, which is sturdy and has a long service life.

2. The frame plate is thick, can resist high torque, and is very strong.

3. Adopt microcomputer (PLC) automatic control, set start, stop, reverse and overload automatic reverse control functions.

4. The equipment has the characteristics of low speed, high torque, low noise, and dust that can meet environmental protection standards.

5. Easy to adjust, low maintenance cost, economical and practical.

6. The thickness of the blade and the number of claws can be changed according to different materials.

Delivery &Shipping for waste paper production line

1.Plastic wraps to protect waste paper production line from dust, moisture and corrosion.

2. Wooden case for compact machine or wearing parts as the outside package. Or according to the customer requirements.

3.Excellant logistic team to guarantee the shredder machines to be safely shipped to customer warehouse, no extra fee on export or import on custom.

Kowloon Service

1. Pre-sales: Provide fitted solution and offer to customers, is able to adjust the layout of complete line to fit customers working area, also provide technical support 24 hours service online.

2. After sales:Kowloon skilled technicians are experienced at oversea installation, therefore they are available to assist with onsite installation, commissioning & training on request. Layout drawing, circuit diagram and maintenance manual will be provided together with our products after sales, so that ensure customers have plenty of time to get prepared for installation.

3. Wearing parts support:Kowloon has widely built extensive cooperation with wearing parts partner manufacturers more than 14years, has ability to continuously provide wearing parts and after-sale service to global market.

Company Introduction

Kowloon Machinery located in industrial hub of Zhenghzou city, China, design and manufacture industrial shredder, wood processing machinery, waste tire recycle equipment and scrap metal recycling machines. Kowloon products approved by CE and ISO certificates. Up to now, we have exported to more than 30 countries and share markets in worldwide, and now are still growing continuously.

We effort on improving and researching, in past years, various of new products were developed and becomes popular in domestic and abroad market, won good reputation and corporate image, we always effort on best quality and service, welcome to inquiry!

| Model | JLSS1000 | JLSS1200 | JLSS1500 | JLSS2000 |

|---|---|---|---|---|

| Motor | 15kw+15kw | 22kw+22kw | 55kw+55kw | 90kw+90kw |

| Gearbox | 2units, Planetary type, Gear transmission | |||

| Shaft | Solid shaft, Made of 40Cr, Hardened and tempered | |||

|

Shredder Chamber (Inner) |

940x725mm | 1140x725mm | 1415x1010mm | 1920x1100mm |

| Rotor Rotary Speed | 8-18rpm | 8-18rpm | 8-18rpm | 8-18rpm |

| Blade Type | Detachable type | Detachable type | Detachable type | Detachable type |

| Blade | 9Crsi, diameter 360mm | 9Crsi, diameter 360mm | 9Crsi, diameter 530mm | 9Crsi, diameter 560mm |

| Lubrication System | With automatic oil lubricator | |||

| Dimension | 3.2x1.3x2.3m | 3.2x2x1.9m | 4.04x2.45x2.6m | 5.48x2.79x3.05m |

| Weight | 6000kg | 9000kg | 14000kg | 26000kg |