Tel/Whatsapp:+86 15649675999

Email:sale@kowloonmachine.com

Tel/Whatsapp:+86 15649675999

Email:sale@kowloonmachine.com

Article published:2023-10-07

How to dispose of Organic Waste as a Resource

Organic waste resource disposal refers to converting Organic waste into useful substances through processing for further utilization. At present, the main waste resource disposal methods include recycling, incineration, composting and landfill. With the development of the industry and the analysis of market usage and application, resource recycling is still a more suitable disposal direction.

Resources are utilized: Through waste resource disposal, the originally discarded waste can be converted into reusable resources, such as power generation, fertilizer production, etc.

Reduce environmental pollution: Traditional waste disposal methods such as landfill and incineration will cause certain environmental pollution, and waste resource disposal can reduce environmental pollution.

Save land resources: The traditional landfill method will occupy a large amount of land resources, and waste resource disposal can reduce the occupation of land resources.

Promote sustainable development: Sustainable development requires us to reduce the negative impact on the environment as much as possible, and waste resource disposal meets this requirement and helps promote sustainable development.

In short, waste resource disposal can not only reduce environmental pollution and save land resources, but also improve economic benefits and promote sustainable development. The process of making RDF (refuse derived fuel) from Organic waste resources can be classified as a kind of waste treatment and Resource recovery methods. Through this process, Organic waste is compressed, crushed, dried and heated to extract and prepare fuel.

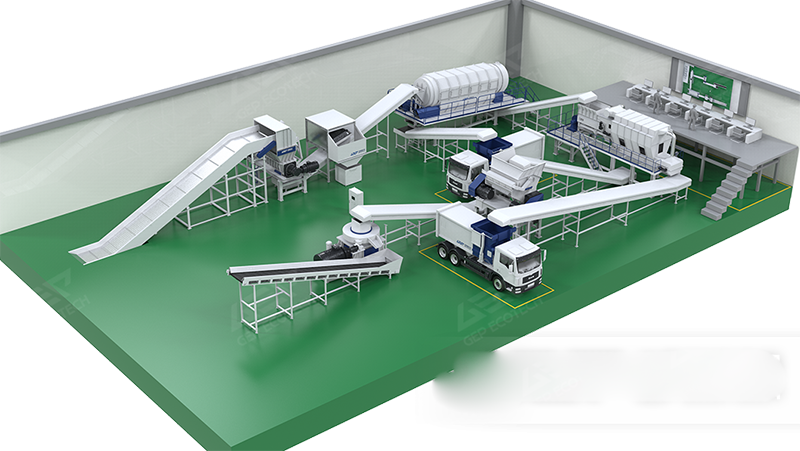

Here are the steps to convert Organic waste into RDF:

Pretreatment: classifying, screening, compressing and drying Organic waste. These steps help extract valuable material for further processing.

Crushing: The pre-processed waste is crushed to make the particles smaller so that fuel can be extracted more easily.

Extraction: Extract the combustibles through equipment such as drum screening or air separation.

Compression: Compress the extracted solid fuel to make RDF. This process can increase the density of the fuel, making it easier to store and transport.

Drying: Dry the RDF to remove moisture. This helps increase the calorific value and combustion efficiency of the fuel.

The process of making RDF helps reduce the amount of Organic waste and improves fuel availability. The fuel could serve as a sustainable energy source for power generation, industrial boilers and other applications. In addition, RDF can also be used as biomass energy to reduce dependence on fossil fuels.